Precision that shapes industries.

Tooling that defines durability.

CEARS Dies & Moulds

Scroll

↓

scroll ↓

CEARS Dies & Moulds

Scroll

↓

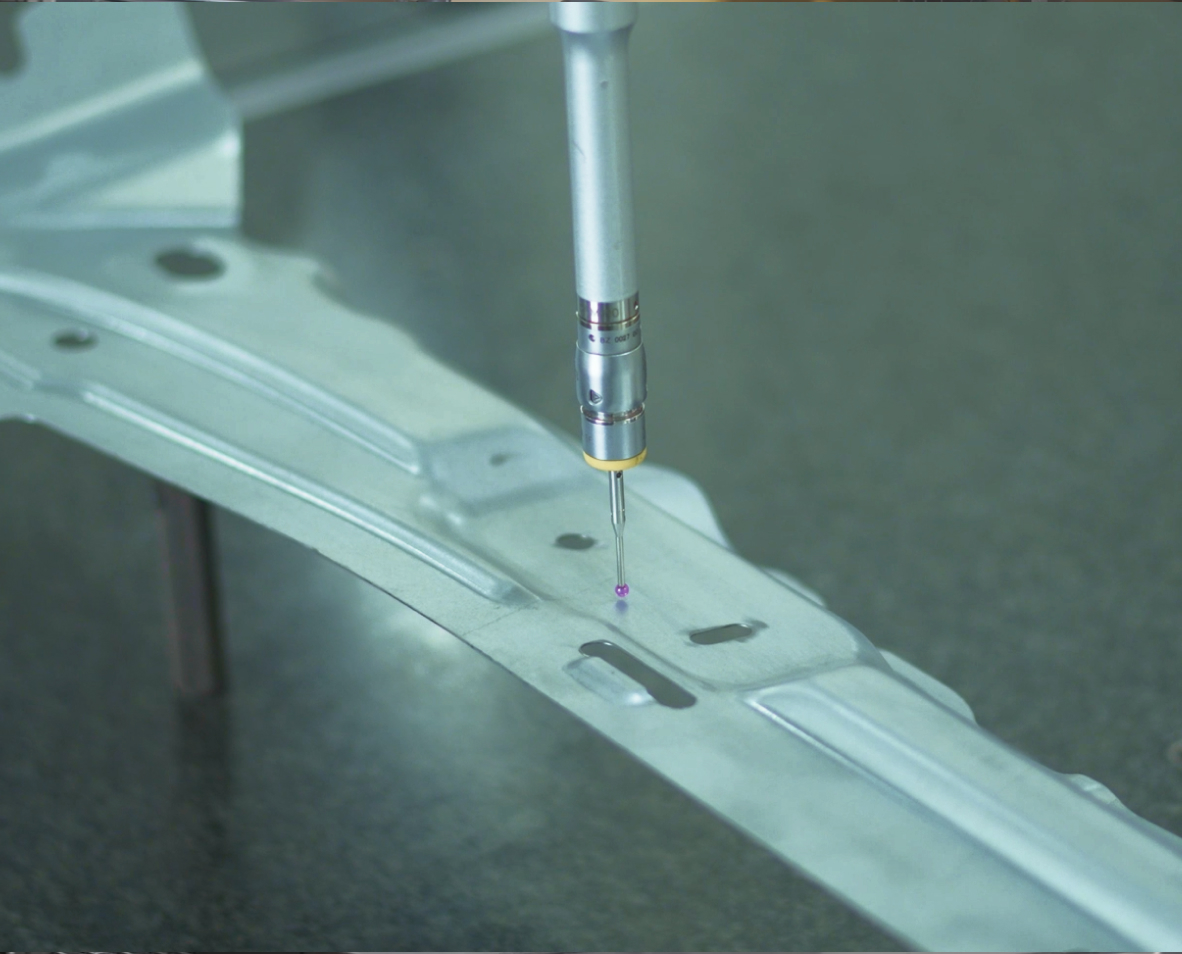

At CEARS Dies & Moulds, we specialize in turning customer designs into precise tooling. For over two decades, we have been manufacturing large stamping dies and prototype assemblies that support some of the most respected names in the automotive industry.

Our capabilities cover progressive, transfer, robotic transfer, and tandem dies, as well as prototype stamping and welded assemblies. To achieve this, we operate advanced Okuma machining centers for high-precision milling and 'A' class surface finishing, along with mechanical presses ranging from 160 tons to 2000 tons.

CEARS is equipped to handle tooling for the latest-generation advanced and ultra-high-strength steels, ensuring that our dies meet the rigorous demands of modern automotive manufacturing. Every stage from design to proving is completed in-house, allowing us to maintain consistent quality and on-time delivery.

We take pride in being a trusted partner to OEMs and Tier-1 suppliers by building dies exactly to specification.

Our toolmaking facility is powered by advanced machining centers delivering ultra-accurate high-precision milling and ‘A’ class surface finishing, supported by mechanical presses ranging from 160 tons to 2000 tons. These machines form the backbone of our die manufacturing workflow, ensuring unmatched consistency even on the most complex components. Alongside machining and press try-out, CEARS maintains in-house assembly, spotting, and inspection capabilities, allowing us to control every stage of die manufacturing and deliver tooling that is precise, reliable, and production-ready.